By Greg Papandrew, Co-founder, DirectPCB

PCB buyers often invest a lot of time at the beginning of their relationship with a supplier, signing non-disclosure agreements (NDAs), spelling out manufacturing specifications, sending quotes, placing orders, etc.

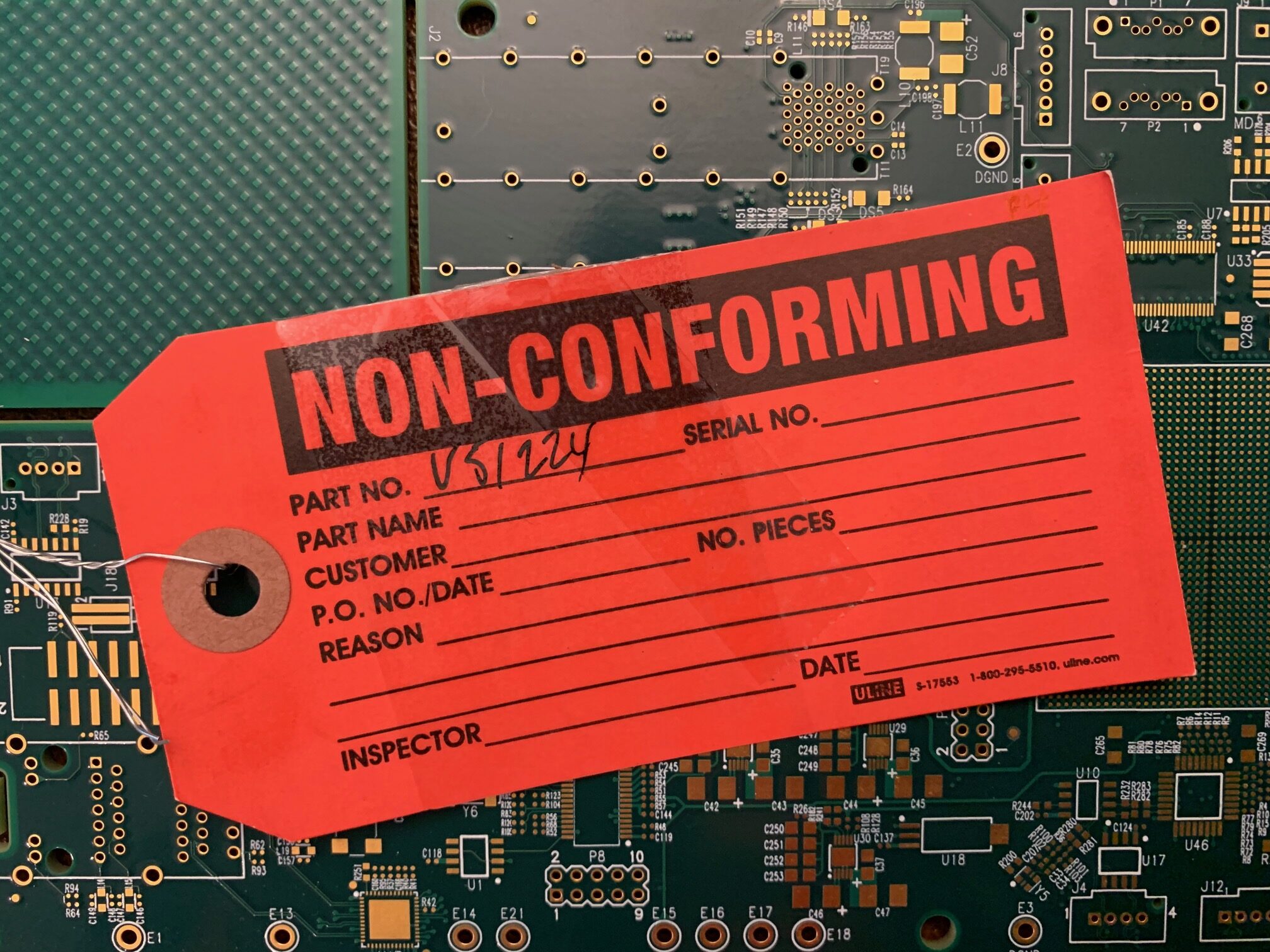

But too often, they don’t put enough time into developing a procedure for handling the inevitable quality problems.

The PCB is a custom-made item that involves over 100 individual processes performed by both humans and machines. In this industry, it is not if but when a quality concern will occur.

Having a documented plan of action in place with each of your PCB vendors—a plan that is fully understood by both parties—will help resolve quality concerns much faster and more easily.

Your plan of action should set clear expectations on what each party will do when a quality problem is discovered, either with unassembled boards or when an assembly is found not to function properly.

You should immediately communicate with the vendor about the problem, providing details such as the part number, the date code, an accurate description of the quality problem, photographs, and most importantly, how many pieces are affected. The more detailed information you can provide, the quicker and more comprehensive the solution will be.

Likewise, you should expect your PCB suppliers to respond in a timely manner, maintain open communication until the root cause of the problem is discovered, and have a possible recovery plan (rework or remake) ready to put in place.

Establish a problem resolution process at the start of your relationship with the vendor, and make sure your PCB supplier is fully on board with the idea. This will help ensure that cooler heads prevail when a quality concern rears its ugly head, and you are more likely to get your board problem resolved swiftly and satisfactorily.

Need to know more about PCB manufacturing or buying? Reach out to me at greg@directpcb.com.

Click here to get a free copy of my book, PCB Basics for Buyers.