𝐁𝐮𝐲𝐢𝐧𝐠 𝐀𝐦𝐞𝐫𝐢𝐜𝐚𝐧 𝐢𝐬 𝐚 𝐧𝐨𝐛𝐥𝐞 𝐠𝐨𝐚𝐥.

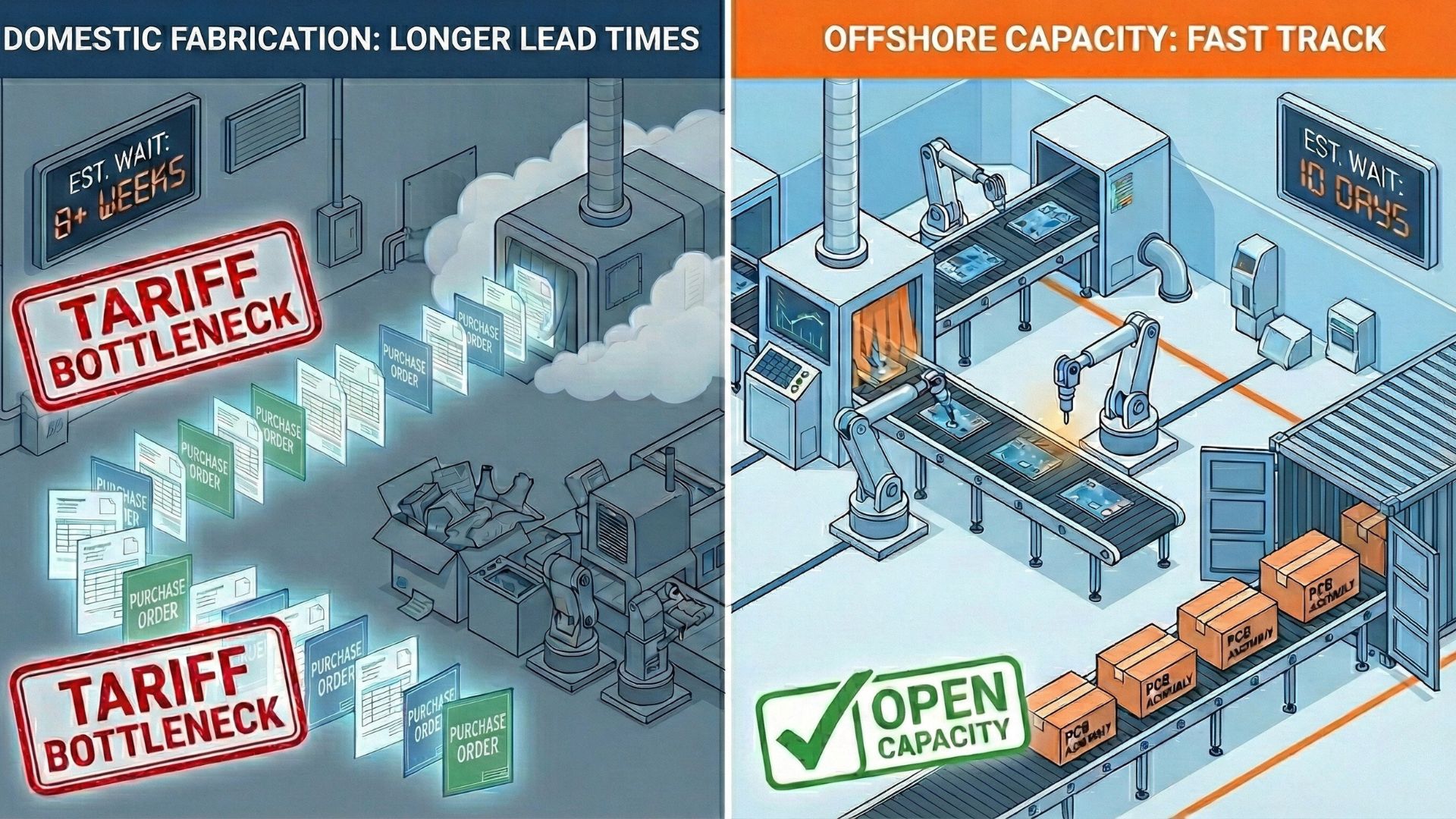

Waiting 8 weeks for product is a business failure.

Last March, I wrote about the looming crunch in US manufacturing capacity. Fast forward to today, and we are seeing the fallout.

Right now, procurement managers are flooding domestic shops with orders to dodge import tariffs.

Business is booming for many domestic shops, but they are operationally drowning. They don’t have all the latest equipment, and more importantly, they don’t have all the required labor to clear the backlog.

Great problem as long as you are not a PCB buyer.

The hard truth: Tariffs create domestic demand, but they do not create domestic capacity. They create bottlenecks.

While your order sits in the manufacturing process for six to eight weeks, offshore shops in Southeast Asia have open capacity, ready to ship in 10 days (notwithstanding the upcoming Chinese New Year holiday).

As long as your order is not an export-controlled item, don’t lose unnecessary PCB assembly time just to avoid a duty tax.

The cost of delay is usually higher than the cost of the tariff.